Always the fastest and most effective solution

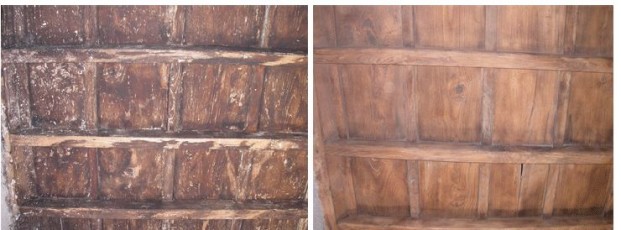

Abrasive blasting is the operation of propelling air by means of a compressor and a mixer of sand and air. This process produces a high quantity of fine dust and needs therefore specific preventive measures during execution. For this reason abrasive blasting is advisable in circumstances when no danger is to be caused by the produced fine dusts and appropriate protection equipment is available.

Surely abrasive blasting is the fastest and most cost-effective solution which can be performed in every period of the year. This method is ideal because it does not stain nor damage the surfaces and internal plasters, enabling the operator to immediately appreciate the final result of the cleaned surface. In addition, there is the possibility to recapture outright and reuse the dust and abrasive materials thanks to an extractor fan included in the brush of the gun.

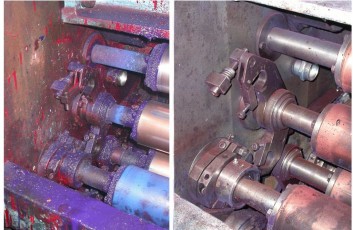

Zamar Srl provides its customers with cost-effective planning and modern technical solutions for the realization of anti-corrosive works and sandblasting in multiple sectors such as the industrial, petrochemical and naval.

Our company avails itself of highly qualified and specialized personnel, regularly trained. In this way it is possible to offer performative solutions for every need. Depending on the surfaces to be treated and the desired results, different variants of abrasive blasting are possible by using compressed air blasters equipped with shots of various materials such as corundum, ceramic and fine glass beads.

Such variants facilitate the manufacturing process of objects which cannot be otherwise wrought by traditional shotblasting machines.