Modern technical solutions

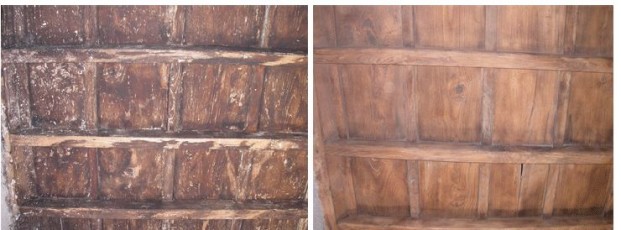

Considering the projects in their entirety, and focusing on the maintenance costs, we are able to state that the anti-corrosive treatment may represent a significant expense. For this reason, a competent evaluation in order to achieve optimal results in terms of cost-benefits is very important.

Our company has developed such competence through to the application of the certified Quality System ISO 9001:2008 and the strict following of the international regulations during the operational phase:

The surface preparation by means of a blasting achieving the specific cleanliness state as required by the laws ISO 8501-1 and Swedish Standard SIS 05-59-00 and included in the customer agreement specifications.

The appliance of anti-corrosive products in the respect of their composition, thickness of the application, operational and environmental procedures in compliance with the SSPC, ASTM, ISO, NACE standards and with the manufacturer technical data sheet.

The application and inspection of the product used and the measurement of the dry total thickness of the entire cycle by means of the suitable equipment previously checked and calibrated.

We give due consideration to the work quality check as an integral part of the anti-corrosive painting process.

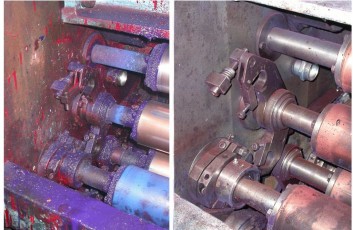

Our company executes painting systems and anti-corrosive services for industrial plants and offshore companies.

Among our services: traditional cycles, epoxy cycles, polyurethanic, silicon-based, organic and inorganic zinc primers.