Modern technical solutions

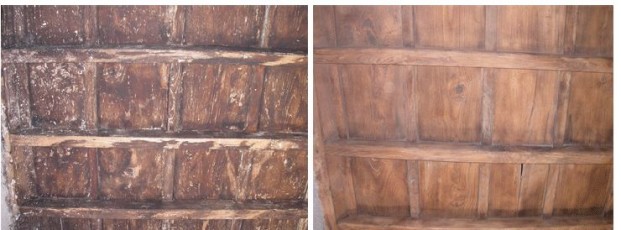

Unlike the abrasive blasting, in the Hydro-blasting method a highly pressured stream of water or a solution of water and a corrosion inhibitor are used.

In the Hydro-blasting process, only a small quantity of residual dust is produced. Thanks to this method, it s possible to remove every kind of impurity from different surfaces, such as marble, granite, cement and swimming pools waterproofing materials.

This method is not always applicable and appropriate, though. For example, hydro-blasting would not be advisable for the cleaning of metal frameworks made of horizontal boards, pointing upwards bars and roods with many cavities since the removal of wet blast would be very difficult.

Zamar Srl provides its customers with cost-effective planning and modern technical solutions for the realization of anti-corrosive works and sandblasting in multiple sectors such as the industrial, petrochemical and naval.

Our company avails itself of highly qualified and specialized personnel, regularly trained. In this way it is possible to offer performative solutions for every need.

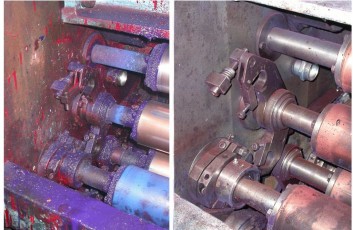

Depending on the surfaces to be treated and the desired results, different variants of abrasive blasting are possible by using compressed air blasters equipped with shots of various materials such as corundum, ceramic and fine glass beads.

Such variants facilitate the manufacturing process of objects which cannot be otherwise wrought by traditional shotblasting machines.