Modern technical solutions

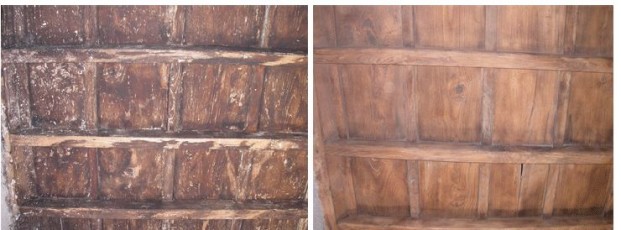

Wet abrasive blasting is the process of surface cleaning by using a highly pressured stream of water and sand, leaving very few dusts residue to clean up.

Wet abrasive blasting can be further classified in two different methods: Hydro-blasting (the water is mixed inside the sandblaster machine), Damper Blasting (the water is taken externally)

During Hydro-blasting a massive quantity of water is needed. For this reason this method is less efficient than abrasive blasting since the use of water decreases enormously the abrasive power of sand.

In addition, all wet abrasive treatments activate an immediate oxidation process on the iron frames. Thus, the application of inhibitor agents on the wet surface is advisable in such cases.

Zamar Srl provides its customers with cost-effective planning and modern technical solutions for the realization of anti-corrosive works and sandblasting in multiple sectors such as the industrial, petrochemical and naval.

Our company avails itself of highly qualified and specialized personnel, regularly trained. In this way it is possible to offer performative solutions for every need.

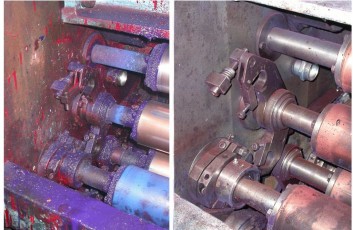

Depending on the surfaces to be treated and the desired results, different variants of abrasive blasting are possible by using compressed air blasters equipped with shots of various materials such as corundum, ceramic and fine glass beads.

Such variants facilitate the manufacturing process of objects which cannot be otherwise wrought by traditional shotblasting machines.